High-velocity pitching has become a defining feature of modern baseball training. As athletes pursue greater throwing speed and improved control, pitching machines and intensive throwing drills now generate significantly higher impact forces than in previous decades. Under these conditions, training infrastructure must deliver exceptional stability, safety, and durability.

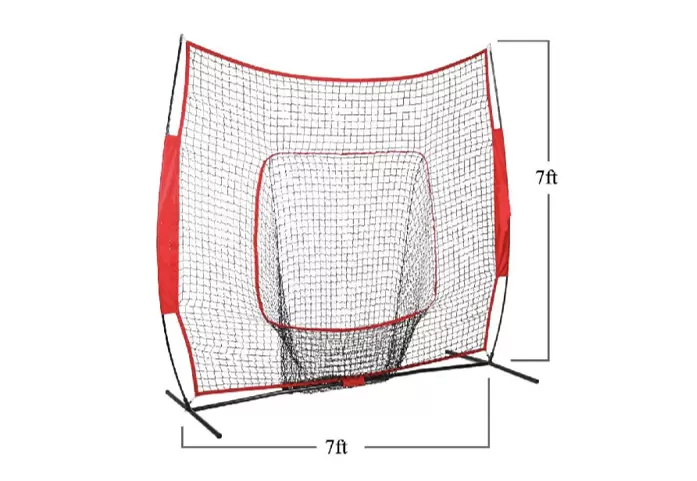

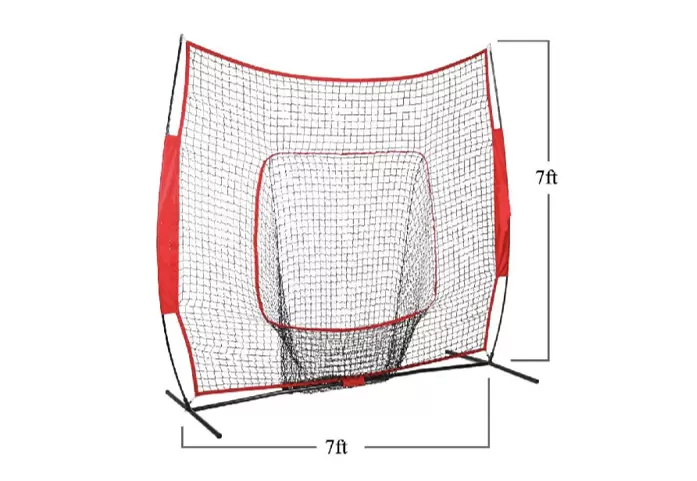

Within this environment, the practice baseball net is no longer a simple practice accessory. It has evolved into a critical structural component that directly influences training efficiency, athlete safety, and long-term facility management. Reinforced steel frame systems developed by Riches Net are engineered to support high-impact pitching environments through advanced material control, precision manufacturing, and integrated production processes.

By aligning professional training requirements with industrial-grade engineering standards, Riches Net provides baseball net systems designed for sustained performance in demanding practice conditions.

The Impact of High Velocity Pitching on Training Infrastructure

Professional and semi-professional pitchers routinely exceed throwing speeds of 140 km/h. At these velocities, repeated ball impact generates concentrated stress on net systems and supporting structures. Without sufficient structural reinforcement, deformation, instability, and premature failure become unavoidable.

Common problems associated with inadequate net systems include:

Frame vibration and displacement

Progressive mesh elongation

Joint fatigue and loosening

Reduced containment accuracy

Increased safety risks

A well-engineered practice baseball net must function as an integrated impact management system rather than a passive barrier. It must absorb, distribute, and dissipate energy efficiently.

Riches Net designs its reinforced steel frame systems to meet these technical requirements through controlled manufacturing and structural optimization.

Material Selection and Steel Frame Engineering

Structural stability begins with material quality. Inferior steel tubing often exhibits inconsistent wall thickness and poor weld integrity, leading to localized weakness under repetitive impact.

Huizhou Riches Net Science & Technology Co., Ltd. maintains strict material control across its vertically integrated production system. From metal pipe manufacturing to surface treatment, every process stage is internally managed.

Core engineering features include:

High-strength steel pipes with controlled thickness

Precision cutting and punching

CNC-guided bending

High-penetration welding

High-temperature baking and corrosion-resistant coating

These processes minimize internal stress concentrations and ensure uniform load-bearing capacity throughout the frame.

Independent sports equipment durability studies indicate that reinforced steel frames can improve structural lifespan by more than 35% compared with lightweight alternatives.

Optimized Frame Geometry and Load Distribution

Frame geometry determines how impact energy travels through the structure. Poorly designed frames concentrate force at corner joints and connector points, accelerating fatigue and structural degradation.

Modern training systems now adopt distributed load frameworks that redirect impact energy across multiple support members. The Riches Net practice baseball net series incorporates:

Reinforced corner brackets

Multi-point anchoring systems

Balanced cross-beam layouts

Optimized welding angles

This configuration reduces peak stress zones and enhances resistance to micro-cracking over long-term use.

Research from sports engineering laboratories shows that optimized load distribution can reduce joint failure risks by up to 28% under continuous impact conditions.

Net Integration and Tension Stability

Frame strength alone cannot guarantee consistent performance. Net tension plays a decisive role in containment accuracy and rebound control. Over time, unstable frames gradually compromise tension systems, leading to sagging nets and unpredictable ball behavior.

Riches Net benefits from full control over both net weaving and metal fabrication. This enables synchronized engineering between flexible and rigid components.

Through controlled knot density, precise mesh spacing, and accurate dimensional matching, each practice baseball net maintains balanced tension profiles throughout its service life.

This integration delivers:

Manufacturing Capacity and Supply Chain Integration

For training centers and distributors, consistent supply and batch uniformity are critical for operational planning. Fragmented supply chains often result in variable quality and delayed project execution.

With more than 23 years of industry experience, Riches Net operates a highly efficient manufacturing network covering:

Wire drawing and weaving

Net assembly

Steel pipe fabrication

Structural welding

Surface treatment

Final inspection

Fully automated production equipment ensures high-volume output without compromising precision. This capacity enables reliable support for large-scale training projects and international distribution.

According to global sporting goods manufacturing reports, vertically integrated suppliers achieve defect rates over 20% lower than multi-vendor production models.

Quality Management and Dimensional Accuracy

High-velocity pitching exposes even minor structural inconsistencies. Small deviations in joint alignment or frame squareness can amplify vibration and reduce containment reliability.

Riches Net applies a complete and scientific quality management system that monitors:

Pipe straightness

Weld penetration depth

Frame symmetry

Mesh uniformity

Coating thickness

Each practice baseball net system undergoes multi-stage inspection before shipment. This rigorous control ensures dimensional stability and long-term structural integrity.

Durability Testing and Lifecycle Performance

Long-term operational value depends on how effectively training systems withstand repeated high-impact cycles. Riches Net conducts durability simulations that replicate years of real-world pitching activity.

Testing protocols include:

Continuous impact simulation

Torsional stress evaluation

Abrasion resistance testing

Environmental exposure assessment

International sports equipment research indicates that reinforced steel frame systems retain over 90% of original rigidity after extended impact cycles, while standard frames often fall below 70%.

This durability profile supports intensive use in professional and institutional training environments.

Market Trends in Professional Baseball Training Equipment

The global baseball training equipment market continues to shift toward industrial-grade structural systems. Several factors are driving this transformation:

Increased emphasis on performance analytics

Growth of private training academies

Rising demand for year-round practice facilities

Greater focus on injury prevention

Industry reports suggest that reinforced-frame net systems now represent more than 60% of premium training infrastructure investments.

Riches Net’s long-term commitment to automated manufacturing and material engineering aligns closely with these evolving market expectations.

Application Scenarios and System Adaptability

Different training environments impose varying structural and operational requirements. Reinforced steel frame systems provide flexibility across multiple settings.

| Training Environment | Primary Requirement | Structural Advantage |

|---|

| Professional Academies | High impact resistance | Reinforced steel joints |

| Sports Universities | Safety and durability | Anti-deformation design |

| Commercial Training Centers | Continuous operation | Fatigue-resistant structure |

| Private Practice Facilities | Compact stability | Balanced weight distribution |

This adaptability allows a single practice baseball net platform to support diverse operational models.

Frequently Asked Questions

How do reinforced steel frames improve pitching safety?

They absorb and distribute impact energy, reducing rebound risks and preventing structural displacement.

Are steel frame nets suitable for indoor facilities?

Yes. Corrosion-resistant coatings and vibration control support long-term indoor use.

How long can reinforced practice nets last in daily training?

With proper maintenance, industrial-grade systems can operate reliably for 7 to 10 years.

Does integrated manufacturing improve performance consistency?

Yes. Internal control over materials and dimensions reduces quality variation.

Why is frame geometry important in pitching nets?

Optimized geometry ensures even load distribution and minimizes joint fatigue.

Manufacturing Expertise Behind Riches Net Solutions

Established in 2000, Huizhou Riches Net Science & Technology Co., Ltd. brings more than two decades of manufacturing expertise to the sports net industry. With experienced technical personnel, advanced automation, and a complete quality management system, the company consistently delivers products with reasonable specifications, tight knots, accurate dimensions, vibrant colors, and long service life.

Its vertically integrated supply chain, spanning wire production, net fabrication, and metal pipe processing, enables full control over quality, cost efficiency, and delivery schedules. Fully automated equipment for pipe production, cutting, punching, bending, welding, and baking further enhances manufacturing consistency.

This comprehensive capability allows Riches Net to support global baseball training projects with reliable, scalable, and professional-grade solutions.

Conclusion: Building Stability into Every Pitch

High-velocity pitching places extraordinary demands on training infrastructure. Without reinforced structural support, instability and premature equipment failure become inevitable.

The reinforced Riches Net practice baseball net steel frame systems address these challenges through advanced material engineering, optimized frame geometry, and integrated manufacturing control. By combining durability, precision, and scalability, these systems deliver long-term value for professional and institutional users.

For organizations seeking dependable baseball training infrastructure, reinforced steel frame solutions are not optional—they are essential.