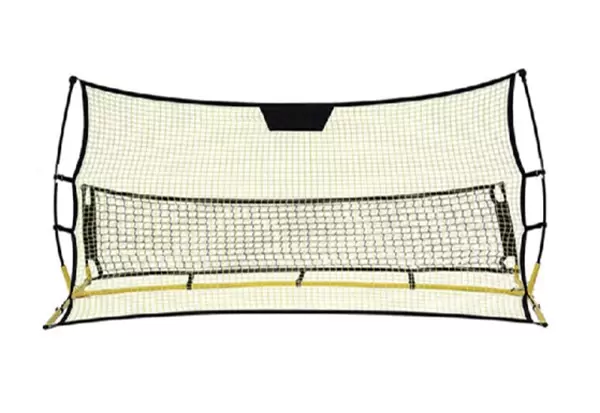

For volleyball enthusiasts, athletes, and coaches, a stable volleyball block trainer is crucial for honing blocking skills, improving reflexes, and simulating real-match scenarios. Riches Net, with over 23 years of industry experience, leverages a fully integrated supply chain to produce volleyball block trainers that combine durability, precision, and portability. From wire production to iron pipe welding, every step is carefully controlled to ensure a product that meets the highest standards of performance and safety.

This article provides a comprehensive view of how Riches Net designs, manufactures, and delivers volleyball block trainers that satisfy both recreational and professional needs.

Black Polyester Knotless Mesh: Striking the Perfect Balance

At the heart of any volleyball block trainer is its netting. Riches Net uses black polyester knotless mesh, which offers:

Three-strand reinforcement (3 strands*1”): Provides exceptional strike resistance, simulating real volleyball impact.

Knotless design: Prevents snagging, improves aesthetics, and ensures consistent ball rebound.

Durable polyester material: Resistant to UV exposure and wear from repeated strikes.

| Feature | Specification | Benefit |

|---|

| Mesh Type | Polyester, knotless | Smooth surface, no snagging |

| Strand | 3 strands*1” | High strike resistance |

| Color | Black | High visibility, minimal visual distraction |

| Size | 90*90cm | Standard block training coverage |

The mesh is carefully engineered to withstand repetitive ball impacts, maintaining structural integrity over time.

Rope Production: Tight Knots and Accurate Dimensions

The quality of the rope system is critical for tension stability and overall durability. Riches Net produces its ropes in-house, allowing control over:

Diameter: Customizable to balance flexibility and strength.

Knot integrity: Ensures tension is evenly distributed, preventing sagging.

Tensile strength: High-quality polyester ropes endure repeated strain without fraying.

In-house rope production ensures consistent specifications for every trainer, critical for professional practice where predictable rebound and tension are necessary.

Iron Pipe Bottom Bracket: Anti-Bending, Anti-Twisting, and Anti-Rust

The base frame defines the trainer’s stability. Riches Net combines PVC-covered, painted iron pipes with rigorous production standards:

Anti-bending and anti-twisting: Reinforced construction ensures the trainer remains upright even after heavy impacts.

Anti-rust coating: Painted and baked surfaces prevent corrosion in outdoor environments.

Optimized geometry: Bottom brackets are designed to distribute weight evenly and maintain center stability.

This structural design guarantees that the block trainer remains safe and reliable during intensive training sessions.

Integrated Supply Chain: From Wire to Finished Product

Riches Net’s fully integrated supply chain allows complete control over the product life cycle:

Wire Production: High-quality polyester strands for mesh and ropes are manufactured in-house.

Metal Pipe Production: Automatic pipe cutting, punching, bending, and welding ensures precision and consistency.

Surface Treatment: Baking and painting pipelines provide corrosion resistance.

Assembly: Nets and ropes are combined with the iron pipe frame under strict quality control.

Packaging: High-capacity Oxford cloth carrying bags are provided for easy transport and storage.

By controlling every step, Riches Net reduces lead times, ensures consistent quality, and offers cost-effective solutions without compromising performance.

Customization Options: Meeting Diverse Needs

Riches Net recognizes that one size does not fit all. Clients can customize multiple aspects:

Product color: Tailor to branding or aesthetic preferences.

Mesh sparseness: Adjust the distance between strands for different rebound characteristics.

Rope thickness: Optimize for durability or flexibility.

Frame size: Modify height or width to suit training facilities or specific skill drills.

Customization ensures that the trainer fits precisely into any training setup, enhancing usability and effectiveness.

Portability: Easy Carrying and Storage

The Oxford cloth carrying bag included with the volleyball block trainer is designed for:

Large capacity: Holds the net, ropes, and iron pipe components in a single bag.

Durability: Heavy-duty fabric resists tearing and wear.

Convenience: Lightweight and easy to carry to beaches, gyms, or practice courts.

Portability ensures that athletes and coaches can use the trainer in various locations without hassle, encouraging frequent practice.

Production Efficiency and Cost Control

The integration of the full supply chain results in:

Lower production costs: No dependency on external suppliers reduces markups.

High-volume production capacity: Ability to scale orders quickly for schools, clubs, and commercial gyms.

Consistent quality: Automated processes reduce variability and defects.

Investing in a supply-chain-integrated manufacturer ensures predictable delivery times and competitive pricing without sacrificing durability.

Durability and Longevity

Every component of the volleyball block trainer is engineered for long-term use:

Polyester knotless mesh resists UV fading and repeated ball strikes.

Reinforced ropes maintain tension and resist fraying.

Painted iron pipe frame withstands rust, bending, and twisting.

This durability ensures a long service life, making the trainer a cost-effective investment for training facilities.

Table: Key Specifications Overview

| Component | Material / Specification | Benefit |

|---|

| Mesh | Black polyester, knotless, 3 strands*1” | High strike resistance, smooth rebound |

| Rope | Polyester, customizable diameter | Strong, maintains tension, durable |

| Bottom Bracket | PVC + painted iron pipe | Anti-bending, anti-twisting, anti-rust |

| Size | 90*90cm (customizable) | Full block coverage, adaptable for different courts |

| Carrying Bag | Oxford cloth, large capacity | Easy transport and storage |

| Customization | Color, rope thickness, mesh sparseness, frame size | Meets diverse training needs |

FAQ: Volleyball Block Trainer Selection

Q1: Can the mesh density be adjusted for beginner vs. professional use?

Yes, Riches Net provides OEM customization to modify mesh sparseness for desired rebound characteristics.

Q2: How weather-resistant is the frame?

The PVC-coated, painted iron pipe is anti-rust, making it suitable for outdoor and beach volleyball environments.

Q3: Is assembly complicated?

No, the trainer is designed for quick assembly without special tools, suitable for coaches, athletes, and students.

Q4: Can the trainer be transported easily?

Yes, the included Oxford cloth bag provides convenient portability for multiple locations.

Q5: What is the expected lifespan under regular outdoor use?

With proper care, the trainer can last 5–8 years, depending on frequency of use and environmental conditions.

Conclusion

Riches Net’s volleyball block trainer exemplifies the advantages of integrated supply chain manufacturing. By controlling wire production, mesh fabrication, rope processing, iron pipe welding, and surface treatment, the company ensures maximum stability, durability, and performance. Combined with customization options and portable design, these trainers cater to beach volleyball enthusiasts, students, athletes, and coaches alike.

Choosing a trainer from a full-supply-chain manufacturer like Riches Net guarantees consistent quality, long-term value, and reliable performance, making it a cornerstone tool for effective volleyball training.