In the global sports equipment procurement landscape, the friction between high quality and low cost is a constant challenge for wholesalers, distributors, and sports academy directors. While the market for portable training gear continues to expand—driven by a surge in outdoor fitness and beach sports—finding a partner that balances precision engineering with price competitiveness is rare.

Huizhou Riches Net Science & Technology Co., Ltd. (Riches Net) has solved this equation. Since our inception in 2000, we have transitioned from a traditional manufacturer to a high-tech powerhouse. Our secret to dominance in the beach training net sector lies in our fully automatic production lines and a vertically integrated supply chain that spans over 23 years of industrial refinement.

I. The Anatomy of an Affordable High-Performance Net: Technical Specs

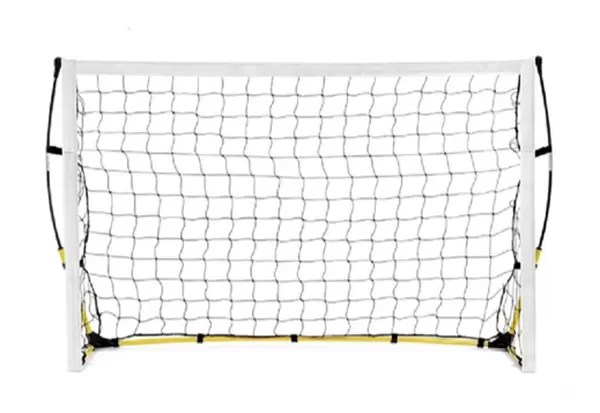

Before examining the economics of our production, it is essential to understand the technical complexity of our 90*90cm portable beach training nets. Achieving affordability without compromising these specific high-performance metrics is what defines the Riches Net B2B advantage.

| Feature | Specification Details | Riches Net Performance Standard |

| Mesh Material | Black Polyester Knotless Mesh | Strike-resistant, high tensile strength |

| Mesh Density | 3 Strands * 1 inch | Optimized for energy absorption and bounce-back |

| Bottom Bracket | PVC + Painted Iron Pipe | Anti-bending, anti-twisting, and rust-proof |

| Portability | High-density Oxford Cloth Bag | Reinforced stitching for high-frequency travel |

| Design Dimensions | 90cm x 90cm (Customizable) | Precise sizing through automated cutting |

II. Vertical Integration: Eliminating the "Middleman Tax"

Most beach training net suppliers are merely assemblers. They source netting from one factory and metal frames from another, adding markups at every stage. Riches Net operates on a completely different model.

We maintain a complete supply chain from wire production to metal pipe fittings. This means we manufacture the raw fibers used for the polyester knotless mesh and process the iron pipes used for the brackets under one roof. By controlling the raw materials, we eliminate external supplier premiums and logistics delays, passing those direct "factory-to-client" savings onto our B2B partners. This vertical control also ensures that our vibrant colors and tight knots remain consistent across bulk orders of 1,000 or 10,000 units.

III. The Economics of Automation in Iron Pipe Fabrication

Automation is the primary driver of our "Ideal and Affordable" pricing strategy. In our iron pipe sector, we have replaced manual labor with fully automatic equipment for:

Precision Cutting & Punching: Reduces material waste to near zero.

Automated Bending: Ensures every 90*90cm frame is identical, preventing the structural "twisting" common in manual production.

Robotic Welding & Baking: Our automated baking paint process creates a uniform anti-rust barrier that is essential for corrosive beach environments.

According to a 2024 Industrial Automation Report, factories utilizing integrated robotic welding and painting see a 25-30% reduction in per-unit manufacturing costs while increasing structural consistency by 40%. At Riches Net, these efficiencies allow us to offer professional-grade equipment at a price point that supports the profit margins of our international distributors.

IV. Engineering for the "Beach Environment" Reality

A beach training net faces unique stressors: salt air, intense UV exposure, and high-impact strikes from athletes. Our technical personnel—many with over two decades of experience—have engineered the 3 strands * 1” strike-resistant mesh specifically to handle these variables.

The use of polyester knotless technology is a deliberate choice. Knotless nets distribute impact energy more evenly than knotted alternatives, significantly extending the service life of the product. When combined with our anti-rust painted iron pipes, Riches Net products provide a lower Total Cost of Ownership (TCO) for schools, coaches, and sports clubs compared to cheaper, non-specialized alternatives.

V. Customization: The Professional Buyer’s Requirement

In the B2B world, one size rarely fits all. Because Riches Net owns the entire production cycle, our customization capabilities are virtually limitless. We support our clients in defining unique market positions through:

Variable Mesh Sparseness: Tailoring the net for different ball types (volleyball, baseball, or soccer).

Rope Thickness & Color: Aligning product aesthetics with a brand’s specific identity.

Branded Packaging: Utilizing our large-capacity Oxford cloth carrying bags as a canvas for OEM branding.

VI. FAQ: Addressing B2B Sourcing Concerns

Q: How does Riches Net maintain quality consistency in high-volume orders?

A: We implement a complete and scientific quality management system. Automated sensors on our production lines detect deviations in pipe thickness or mesh tension in real-time, ensuring that the 10,000th net is as precise as the first.

Q: Can the 90*90cm net withstand professional-level strikes?

A: Yes. The 3-strand polyester mesh is specifically designed for high-velocity impact. Our "strike-resistant" rating is the result of decades of testing in our scientific quality labs.

Q: What makes your "Anti-Rust" treatment different?

A: Unlike simple spray painting, our pipes go through a fully automatic baking process. This ensures the paint bonds at a molecular level with the iron, preventing the chipping and subsequent corrosion that typically occurs in sandy or humid beach settings.

Q: Is Riches Net capable of supporting rapid prototyping for new designs?

A: With over 23 years of experience and in-house technical personnel, we can rapidly adjust our automated settings to produce custom prototypes based on your specific requirements within tight deadlines.

VII. Conclusion: Scaling Your Business with Riches Net

In an era where supply chain transparency and cost-efficiency are paramount, Huizhou Riches Net Science & Technology Co., Ltd. stands as a pillar of reliability. Our transition to fully automatic production isn't just a technical upgrade; it is a commitment to our B2B partners. By reducing human error and material waste, we provide high-performance beach training nets that are both "Professional" in the eyes of the athlete and "Affordable" in the hands of the buyer.

Whether you are a global sports brand looking for a reliable OEM partner or a regional distributor seeking to dominate the outdoor training market, the Riches Net advantage is clear: Precision manufacturing at a price that powers your growth.