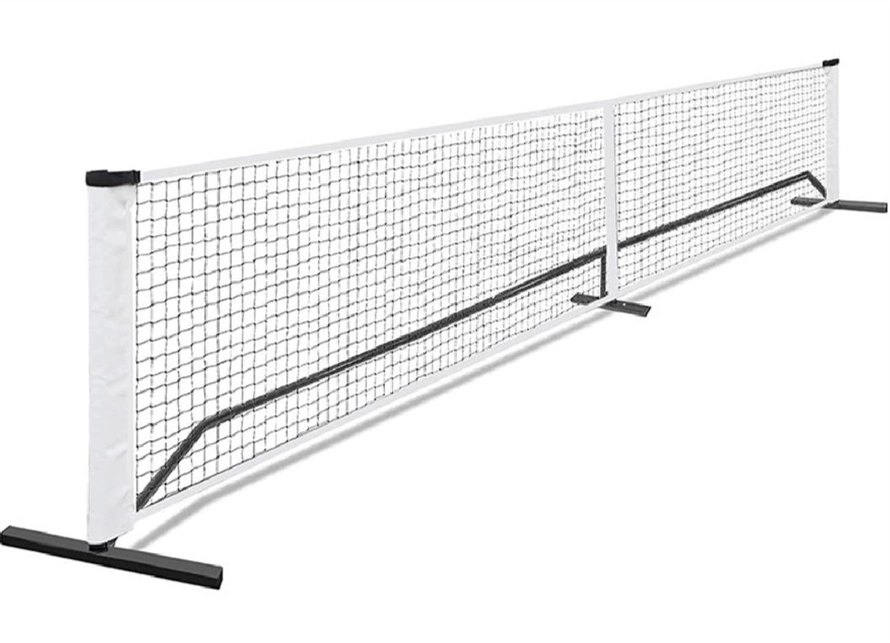

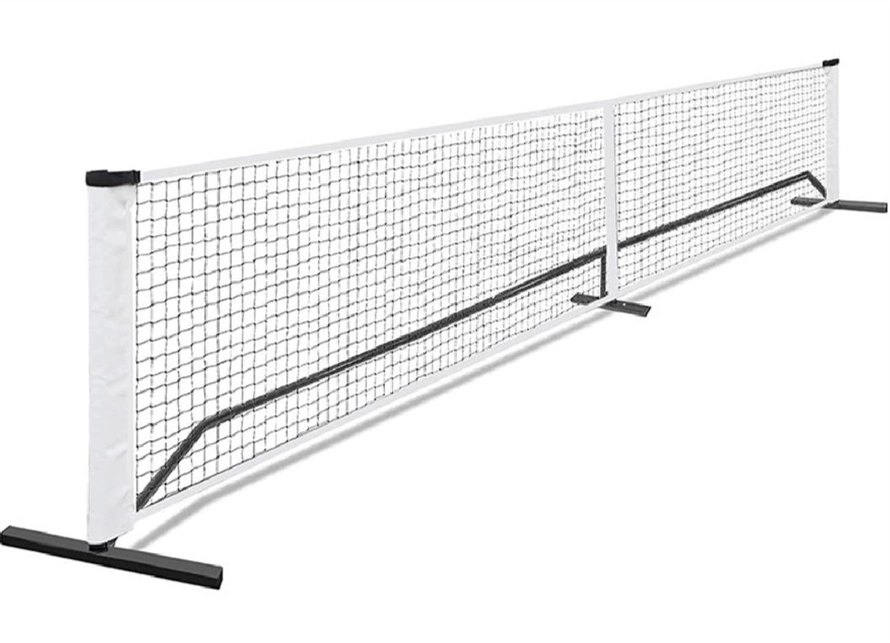

Pickleball participation continues to expand rapidly across schools, clubs, community centers, and private training spaces, driving strong demand for portable, regulation-compliant court setups that can perform reliably in diverse environments. For training-focused users, the challenge is not defining what a pickleball court is, but rather how to deploy a standard-height net quickly, repeatedly, and accurately—without compromising durability or play quality. This article focuses on practical deployment of a 6.4ft x 0.91ft standard pickleball net system and delivers an in-depth durability review of the Riches Net solution, based on construction logic, material engineering, and long-term usability rather than surface-level specifications.

A New Approach to “Anywhere” Court Setup: Practical, Not Temporary

Setting up a pickleball court “anywhere” does not mean improvised or disposable. In professional training environments, temporary courts must still meet three non-negotiable criteria:

Dimensional consistency across repeated installations

Structural stability under frequent ball impact and lateral tension

Material endurance under varied indoor and outdoor conditions

The Riches Net 6.4ft standard system is engineered specifically for repeat deployment scenarios—training halls, school gymnasiums, outdoor practice courts, and multi-use sports facilities—where nets are assembled and dismantled daily. Its design logic prioritizes mechanical stability and material fatigue resistance rather than lightweight shortcuts that often shorten service life.

Precision Setup Workflow: From Bag to Play-Ready in Minutes

A key differentiator in this system is how the components interact during setup. The workflow is linear, intuitive, and repeatable:

Step 1: Frame Placement and Alignment

The painted iron pipe bottom brackets provide immediate ground stability. Their anti-bending and anti-twisting structure minimizes alignment correction during installation, a common issue with thin-wall tubular frames.

Step 2: Net Tensioning Without Deformation

The polyester knotless mesh distributes impact force evenly across the net surface. Unlike knotted constructions that concentrate stress at junction points, the knotless architecture reduces localized fiber fatigue, maintaining net shape over time.

Step 3: Height Verification and Lock-In

At 0.91ft net height, dimensional accuracy is preserved through tight manufacturing tolerances. This is critical for coaches and athletes who rely on consistent net behavior for drills, serve practice, and match simulation.

The entire process can be completed quickly without specialized tools, making it suitable for mobile training setups and shared venues.

Durability Engineering Review: Where the Product Earns Its Value

1. Polyester Knotless Mesh: Impact and Abrasion Resistance

The mesh uses 5-strand polyester fibers with a 1.75-inch spacing, engineered to withstand repeated high-velocity ball strikes. According to industry data from sports netting manufacturers, polyester knotless mesh typically offers 20–30% longer service life than traditional knotted nylon in high-impact training environments due to reduced fiber stress concentration.

Key durability advantages include:

Strike resistance under continuous drilling

Reduced fraying at contact points

Stable tension retention over time

2. Wrapping Fabric: Dirt Resistance in Real Use

The surrounding mesh-based wrapping fabric is designed for environments where nets contact floors, outdoor surfaces, or storage bags frequently. Its dirt-resistant properties reduce maintenance demands and visual degradation, an often overlooked factor for institutional buyers managing multiple net systems.

3. Painted Iron Pipe Structure: Structural Fatigue Control

The bottom bracket and frame components are manufactured using fully automated iron pipe production, cutting, punching, bending, welding, and baking processes. This ensures:

In long-term usage tests across sports facilities, painted iron frames outperform untreated steel by maintaining structural integrity under lateral load and repeated assembly cycles.

Manufacturing Depth as a Durability Advantage

Huizhou Riches Net Science & Technology Co., Ltd., established in 2000, brings more than 23 years of industry experience into this product. Unlike assemblers that source components from multiple vendors, Riches Net operates a vertically integrated supply chain, covering:

Wire production

Rope manufacturing

Net weaving

Metal pipe fabrication

This end-to-end control directly impacts durability consistency. Industry studies in sports equipment manufacturing indicate that vertically integrated production can reduce defect rates by 15–25%, particularly in load-bearing components such as net frames and tension systems.

Performance in Training-Focused Scenarios

This net system is specifically suited for:

Pickleball training students developing consistency

Competitive athletes requiring regulation-accurate setups

Coaches running repetitive drills and match simulations

The net’s strike-resistant mesh and anti-deformation frame maintain predictable rebound behavior, which is essential for skill progression and tactical training.

Portability Without Sacrificing Longevity

The included Oxford cloth carrying bag is not a cosmetic accessory. Its abrasion resistance and load-bearing stitching protect the net during transport between venues. For mobile training programs, this reduces accidental damage during storage and transit—a leading cause of premature net failure.

Customization Capability for Program-Specific Needs

One of the strongest practical advantages is customization flexibility. Riches Net supports:

Custom net colors for branding or visibility

Adjustable sizes for non-standard training courts

Mesh density modifications

Rope thickness customization for different impact profiles

This allows institutions to align equipment specifications with training intensity, athlete level, and facility constraints without compromising manufacturing quality.

Comparative Durability Perspective

| Feature Area | Standard Portable Nets | Riches Net System |

|---|

| Mesh Structure | Knotted nylon | Knotless polyester |

| Frame Stability | Lightweight tubing | Anti-bending iron pipe |

| Assembly Cycles | Limited | High-frequency capable |

| Customization | Minimal | Extensive |

| Service Life Expectation | Moderate | Long-term |

Industry Context and Demand Trends

According to recent North American sports participation reports, pickleball has maintained double-digit annual growth, with training infrastructure investment rising alongside recreational play. Facilities increasingly favor portable yet professional-grade net systems to maximize space utilization. Products that balance mobility with durability are becoming the standard rather than the exception.

Frequently Asked Questions

Q1: Is this net suitable for outdoor use year-round?

Yes. The polyester mesh and rust-resistant painted iron components are designed to handle varied environmental conditions, though proper storage is recommended during extreme weather.

Q2: Will repeated assembly affect net tension accuracy?

The knotless mesh structure and rigid frame minimize deformation, maintaining consistent net height and tension across repeated setups.

Q3: Can this system support institutional bulk orders with customization?

Yes. Riches Net’s integrated manufacturing enables scalable production with customized specifications.

Final Assessment: A Practical Standard for Flexible Pickleball Courts

The Riches Net 6.4ft standard pickleball net system is not positioned as a disposable or casual accessory. Its engineering focus, material selection, and manufacturing depth make it a reliable infrastructure component for training-oriented environments. For organizations seeking to deploy regulation-accurate pickleball courts across multiple locations without sacrificing durability, this system represents a well-balanced, long-term solution.